Snack Series

A long shelf-life and an anytime perfect product is essential for Snack Filling Machinery. Thanks to our modified atmosphere technology we can reach below 0.5% O2 inside the can. Hereby our V-matic system sets a new benchmark regarding quality and efficiency.

The Swiss Can Machinery net weight fillers are an accurate and versatile method to fill different snacks. The dosing of a product is effected by weight, with a highly accurate SIWAREX control. The net weight filling system controls the vibrating feeding channels according to the products weight, like that each portion is exactly well-disposed.

Our innovative Technology enables you to to seam Cans or Jars on the same machine. Just by changing some adjustments the machine can be switched from Cans to Jars in a few minutes. Also different container formats can be exchanged very quickly.

Swiss Can Machinery filling machines have an unique automatic optimizing process in order to adjust to the permanently changing filling conditions – not only in favour of the accuracy, but also for the capacity. After an unique basic adjustment of the requested parameters to the various filling products, the requested filling as per product, weight, tolerance, etc. can be retrieved at any time via HMI. The machine calculates the respective adjustments itself from the parameters and optimises automatically during the current fillings. Changes of the conditions as differences in bulk material (piled weight, flow rate) or in the environment (temperature, air humidity) are recognized automatically and corrected accordingly.

On our filling machines, the filling product is vibrated into the can (if necessary) in order to attain the right free space (between product and lid). To prevent dust developments, dust collection is effectively carried out at the right positions. The filled can is weighted with feed-back control. A can that does not fulfill the parameters is automatically rejected. The memory verifies the accuracy and the weighted quantities easily and the results are saved on a USB-Stick or via Master Control.

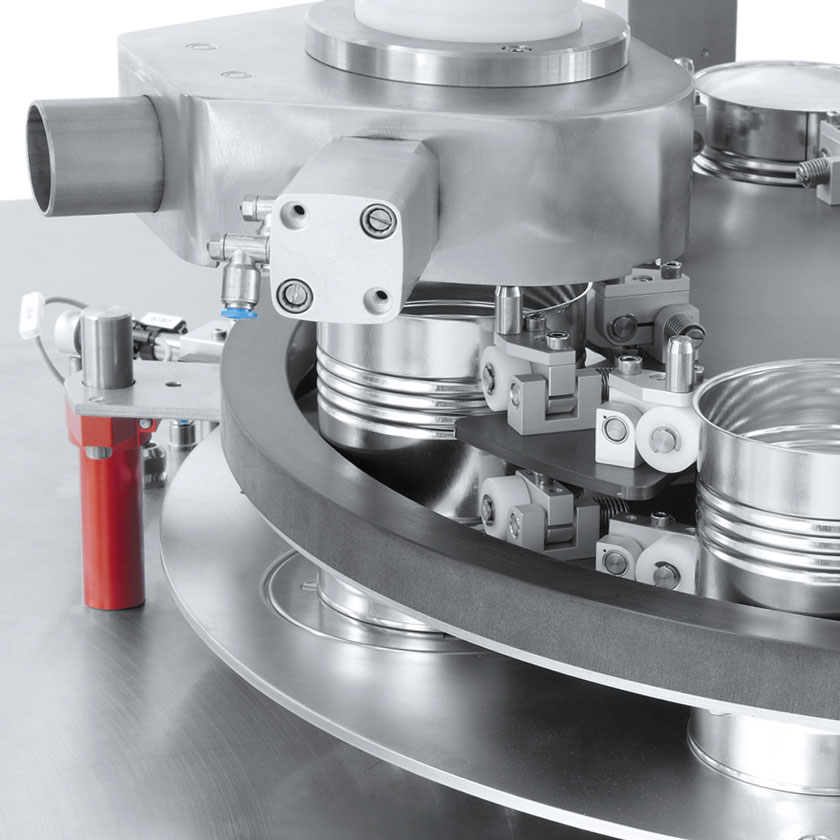

Swiss Can Machinery AG has developped a new gassing system and set a new benchmark regarding efficiency and quality for powder filling in cans. With this development, Swiss Can Machinery is taking a major step towards complying with the ever-increasing trend for gassed cans for all food products. This new process enables the Swiss Can Machinery can closing machine to achieve perfect gasifying of cans at normal speed. The result is vastly improved effectiveness. The cost-benefit ratio for this system is very high. As a result, cans now can be gasifyed without any major increase in complexity. For the first time, tin cans with tin lids and composite cans with tin or cardboard lids can be securely filled, gasifyed and closed with one single, compact and cost-efficient machine.

By essential shortening of process times in the single vacuum stations with the V-matic procedure, it is nowadays possible to make machines for powder in a technology as they were formerly only applied in the pharmaceutical industry for very expensive products like vitamins. This technique does not only guarantee perfect safety for every single can, but also a quality performance standing up to every comparison with other methods. The gas consumption of the V-matic system is extremely low, and also the use of CO2 is not necessary, as the underpressure is made mechanically. Like that, costs can be saved and the system is very environment-friendly. The vacuum chambers of the seaming machines are automatically cleaned of possible milk powder residues and sucked out after each process. This way nothing can happen even then when small quantities of powder dust come out of the can during evacuating.